A question that architects and builders are interested in today: How can modern automation and robotics technology be used more effectively to deliver projects and generate revenue? The importance of automation and robotics technology in architecture. To more accurately determine attitudes toward adopting robotics in practice, architects should think back to their education. Architecture students are often introduced to the concepts of industrial automation and autonomous robots through the myths of the "master builder," who is considered the historical ancestor of today's architects, who oversaw the design and the construction of buildings and structures.

Thanks to this long-awaited industry event, a fleet of next-generation robots will be able to navigate the city's sidewalks more confidently and productively. Serve Robotics in January announced the introduction of next-generation autonomous delivery robots, making it the first manufacturer to deliver commercial orders at Level 4 autonomy. The event demonstrates that the latest robot from Serve Robotics can operate without human input and rely on built-in capabilities for safe operation. It is the industry's first result of nearly five years of work by Serve Robotics experts and is a significant step forward in the autonomous vehicle industry, significantly reducing the barriers to autonomous delivery on an industrial scale.

Employees at China's Three Mountains University have developed an industrial robot that can imagine human thoughts with almost 100% accuracy. Such "cobots" will dominate factories shortly, replacing inexperienced workers.

Robots can cut production costs in half

Developers from the Institute of Innovative Intelligent Manufacturing Technology tested a robot in a Chinese factory. With the help of a team of 8 volunteers, including assembly line workers, the robot underwent hundreds of hours of training. The new development was called "cobot," which means "collaborative robot. Such a robot is expected to do assembly line work alongside humans.

A significant advantage of mobile robots is their computer vision capabilities. The combination of sensors that mobile robots use to determine their environment tracks the environment in real-time with high accuracy. This is important, especially in production environments where the situation constantly changes. The integrated intelligent systems used in AMR offer an additional advantage. Thanks to the autonomy of mobile robots, they can explore the environment using downloaded blueprints or by moving and mapping. This allows rapid adaptation to new environments and further increases productivity in the industry.

Mobile robots are software-controlled machines using sensors and other technology to detect and navigate their environment. Mobility robots operate using a mix of artificial intelligence (AI) and technical elements (legs, chassis, tracks).

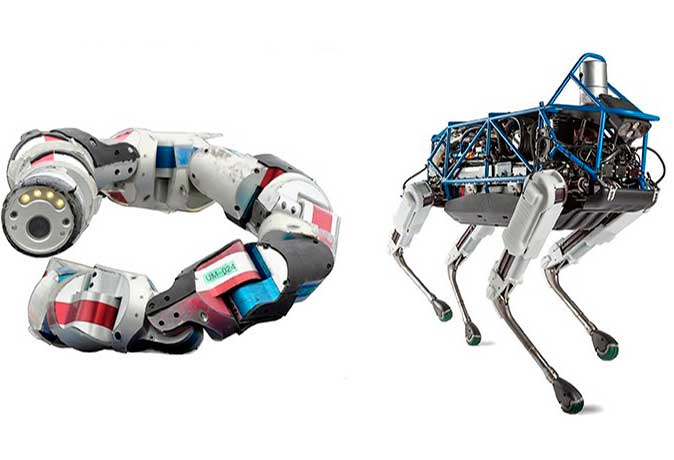

Mobile robot types and classifications

Mobile robots can be categorized in two ways, depending on the environment in which they operate and the movement device.

Given what we've all experienced in the last 2+ years, looking ahead, there are 5 trends for the world of industrial automation.

Manufacturing repurposing. Over the past 2 years, we've seen everything from a shortage of toilet paper to a lack of chips for semiconductors. The shortage of chips has led to a massive hole in the industry, from cars to appliances, with all manufacturers feeling the pressure. Most of the semiconductors in the world today are made in China and Taiwan.